Inkjet printing, a printing process developed for industrial applications, offers unique solutions, a wide range of applications and is also an innovative printing process.

In recent years, a great deal of attention has been paid to this printing process: in addition to the further development of print heads and equipment technology, there have also been major advances in the field of ink systems.

Especially for users of UV or LED curing processes, the inkjet process offers innovative concepts and solutions.

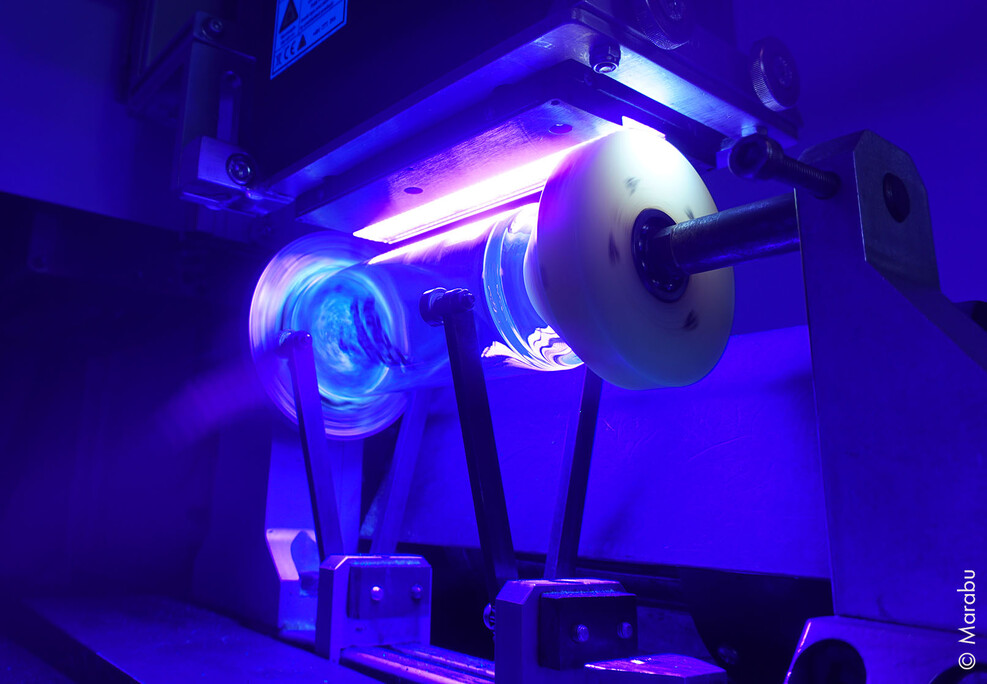

In the printing process, the ink is continuously applied to the substrate without contact. The curing unit (UV or LED) installed in the printer then hardens the print in fractions of a second and is ready for the next finishing process or process step.

As in all areas of digital printing, this printing process offers the greatest possible flexibility in terms of customisability. This starts with a single piece for collections or samples, goes on to very small series and extends to large industrial production quantities - and this especially from the point of view of economic efficiency.

Advantages:

Due to the contactless printing process, the inkjet process is ideally suited for use in numerous industrial applications, such as 3D materials. An incredible variety of materials can be printed, from rigid to flexible items in almost any shape and size. Marabu offers numerous ink systems within the UV/LED inkjet range for materials to be printed, such as

Depending on the application, pre-treatment of the substrate may be necessary to avoid "running" of the ink and to ensure sufficient adhesion of the inks to the surface.

Your Contact:

Customer Service

Email:digitalorders@marabu.com

Marabu is your development partner for projects where the compatibility of the application is paramount or the advantages of UV/LED systems in general outweigh the disadvantages.

Our Expertise:

UV- and LED-curing digital printing inks cure to a solid polymer film by exposure to the corresponding UV or LED light, which is permanently installed in the digital printing system. The stimulus of the UV/LED light causes the photoinitiator in the ink to decompose and start a chain reaction with monomers (building blocks for the later polymer film). The polymerisation was initiated by the light and the liquid ink reacts in fractions of a second to form a solid ink film.

Due to the high three-dimensional cross-linking that takes place during polymerisation, the ink film impresses with its durability and scratch resistance. As a 100% system, UV/LED inks are practically solvent-free. No VOC (volatile organic compounds) are released into the atmosphere. UV/LED inks are emission-free, sustainable and therefore more in demand than ever before.

In addition to purely graphic applications in the wide format segment, UV/LED inks are used for printing on cylindrical objects made of glass or plastic, for example. The range of applications is huge and is constantly expanding.

Direct printing on glass

With the Direct-to-Container concept, Marabu offers new standards. It is quick and easy to print directly onto glass. A label is no longer necessary! Both the high scratch resistance requirements of the beverage bottle industry and dishwasher resistance are met. In addition to cylindrical objects, printing on flat glass is of course also possible:

The advantages of UV/LED-based digital inks: